End-to-end product engineering

You have the idea, we make it become reality. High-speed Linux board, enclosure, operating system, security, and field update infrastructure. We have you covered.

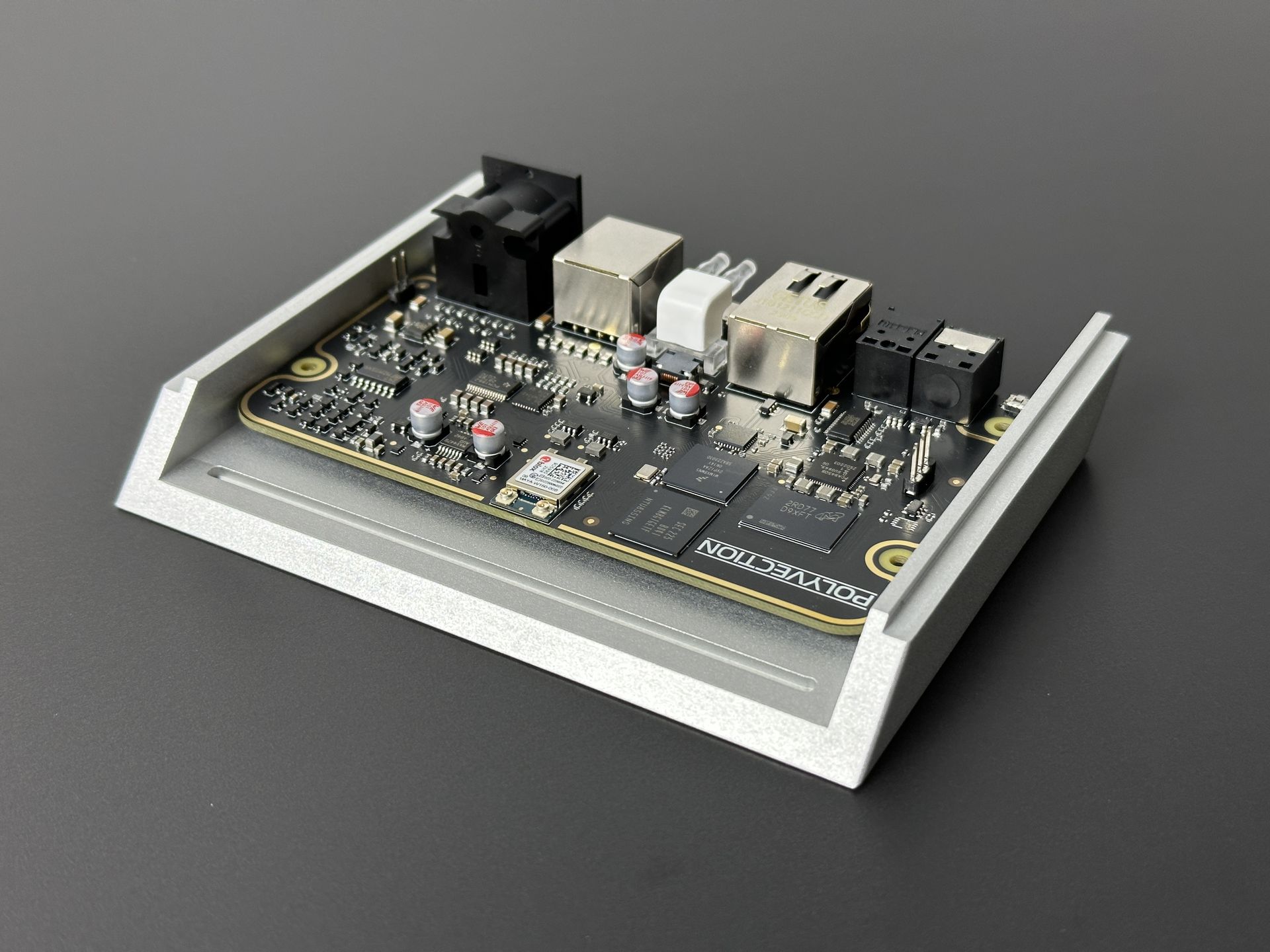

High-speed Linux board design

Complex multi-layer PCBs around NXP i.MX8/93/95, TI AM6x, or Rockchip RK35xx — with LPDDR4/5, PCIe, GbE, and your custom peripherals. No SOM limitations.

Enclosure & mechanical design

Custom metal and plastic housings with thermal management, connector cutouts, and mounting. Designed together with the board — not as an afterthought.

Yocto Linux OS

Custom distribution built for your hardware. Clean BSP layer, reproducible builds, kernel and u-boot tuned for production — not a dev-board image.

Security & OTA updates

Secure boot chain with hardware root of trust, signed images, and A/B updates with rollback. Your devices stay updatable and protected in the field.

Product compliance

EMC, RED, CE — we design for compliance from the start and run pre-compliance testing in our own EMI lab before the external test house.

Full IP handover

Schematics, layout, BOM, Yocto source, build scripts, manufacturing data. You own everything and can continue independently — with any team, any CM.